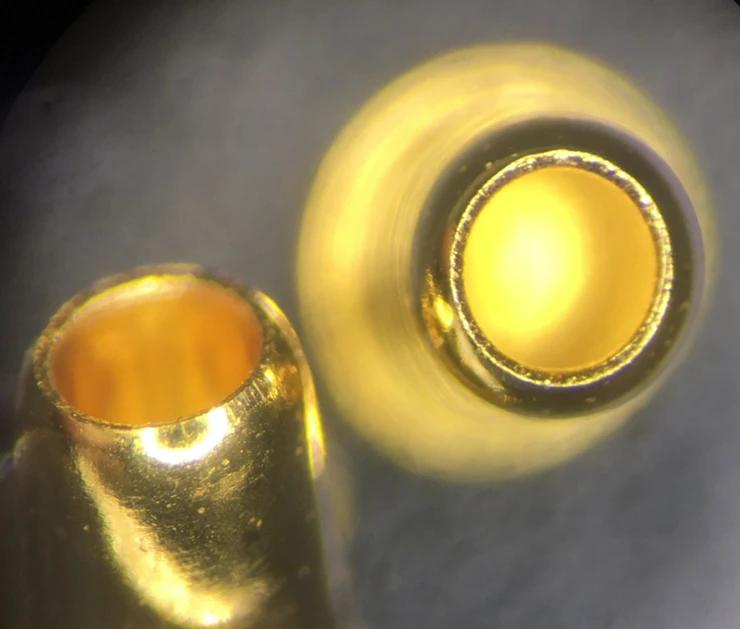

- Innovative design:Slope Structure Design,More Stable Contact, Lower Resistance

- Installation method: SMT Surface Mount (SMD) Reflow Soldering or Placement by Insertion Machine and Fixation by Wave Soldering

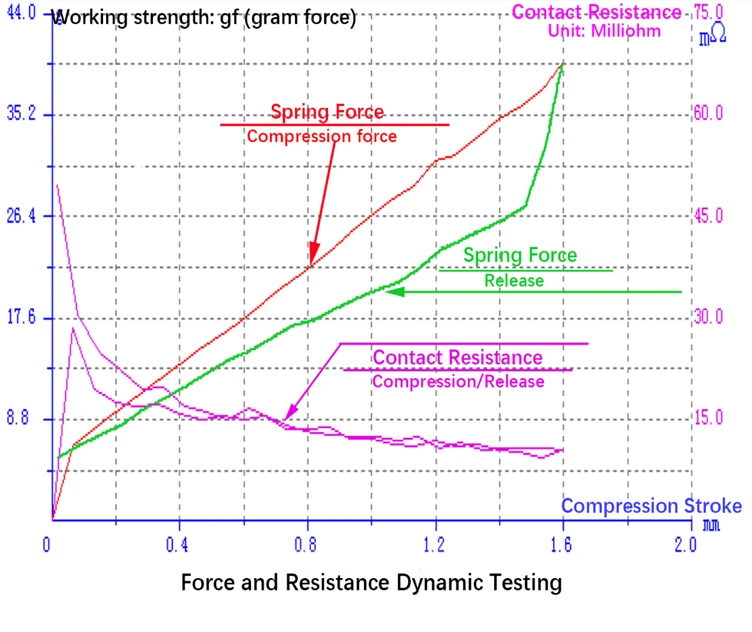

- Contact Resistance:30 milliohms Max.

- Rated Current:10A-30A(Continuous Current)

- Rated Voltage:36V AC/DC

- Durability:Min.10,000 Times(Reciprocating Motion Lifespan)

- Operating Temperature: -40°C to +120°C(Continuous Temperature)

- Salt Spray Resistance 96 Hours Corrosion Test

- High-Precision Mold And Parts Processing

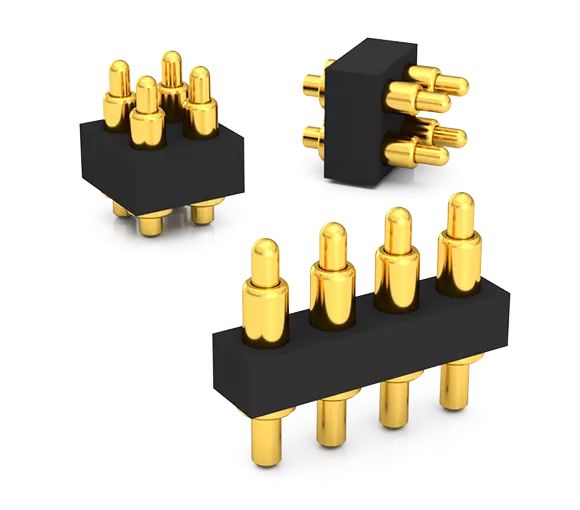

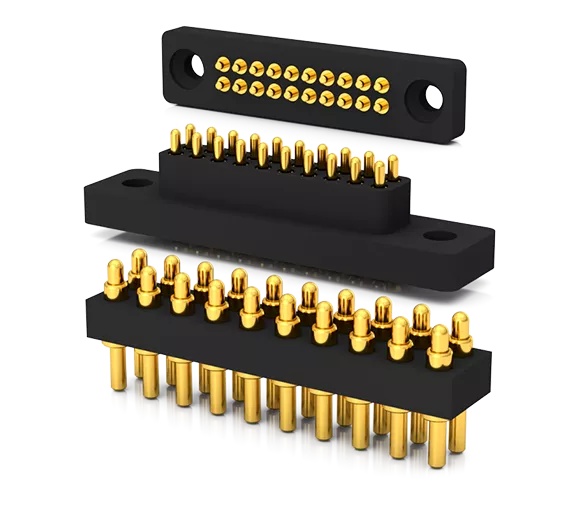

- A variety of standards are available, and samples will be sent out as soon as the same day.

- Provide Customized Services

- Comply With EU RoHS And Reach Standards

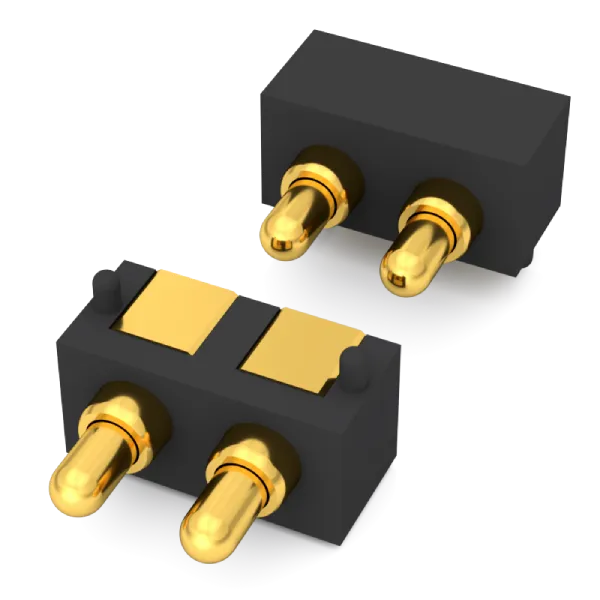

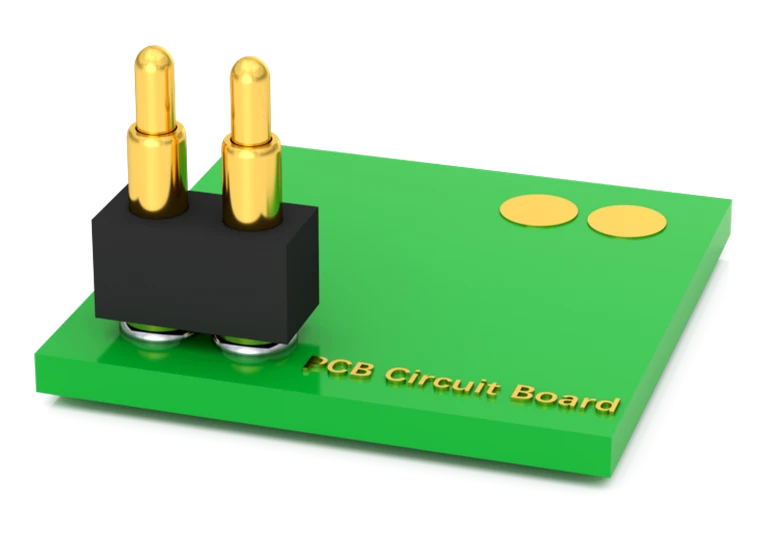

2Pin vertical DIP Pogo Pin connector application

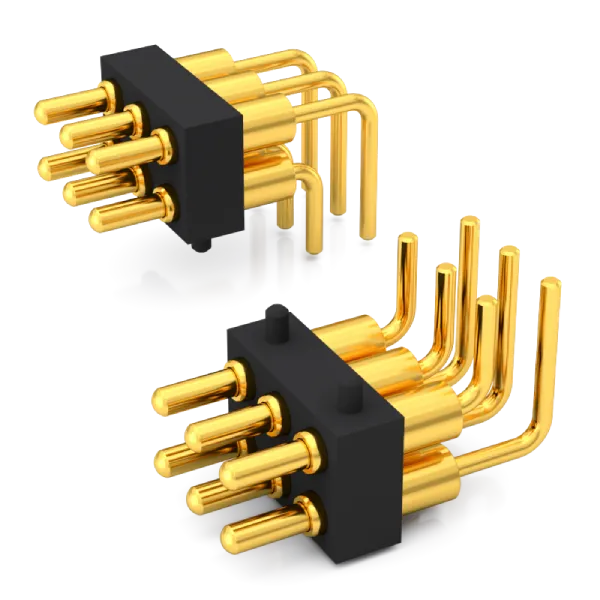

Installation methods for Vertical Dip Pogo Pin Connectors include:

SMT Automatic Pick-and-Place Reflow Soldering Technique: An SMT automatic pick-and-place machine accurately mounts the Vertical Dip Pogo Pin Connector onto a PCB that has been pre-printed with solder paste. The connector’s pins are precisely inserted into the PCB holes, and then the reflow soldering process melts and solidifies the solder paste, securing a fixed connection with the PCB pads. This process is fast, highly precise, and highly automated, significantly improving production efficiency and product quality.

Automatic Insertion Machine + Wave Soldering Technique: An automatic insertion machine accurately mounts the Vertical Dip Pogo Pin Connector onto a PCB pre-printed with solder paste and inserts the pins into the board. The wave soldering process then melts and secures the solder paste, completing the fixed connection with the PCB pads. This process is quick, precise, and highly automated, greatly enhancing production efficiency and product quality. It is suitable for electronic components with extra-long pins that cannot be fixed by SMD reflow soldering.

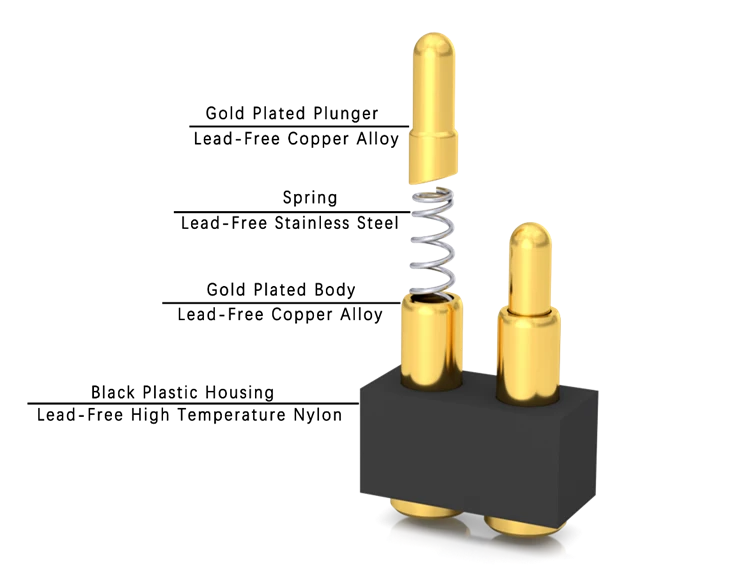

Pogo Pin connector materials and parts composition

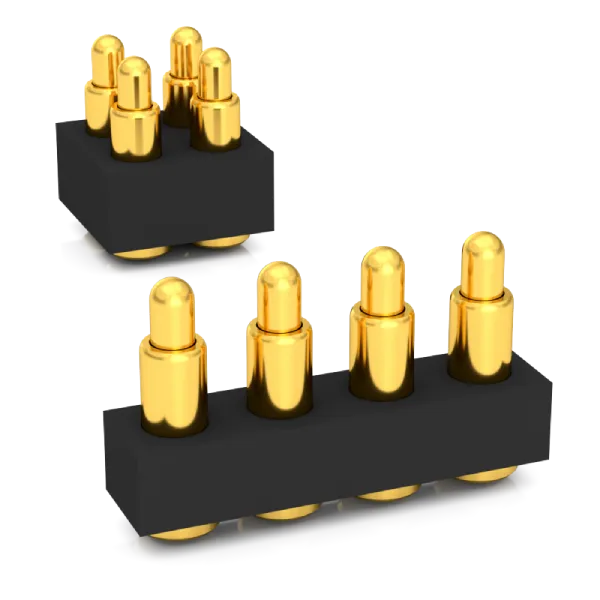

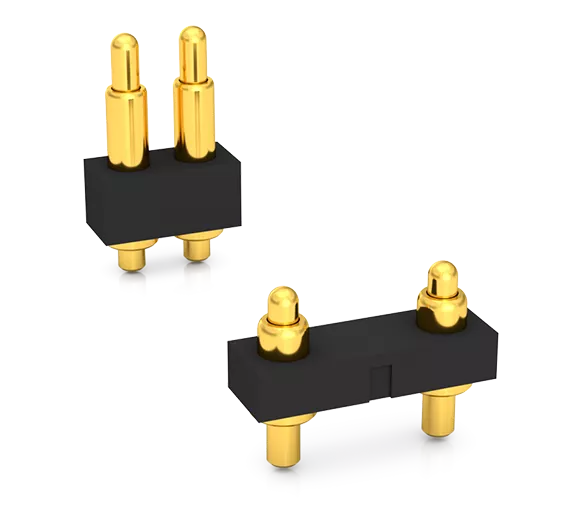

The Vertical Dip Pogo Pin Connector is a variant of Pogo Pin connectors, engineered with a slanted surface structure and incorporating a built-in spring mechanism. It is chiefly comprised of two fundamental components: the Pogo Pin and the housing. Characterized by its vertical contact orientation, it comes with integral solder legs, making it apt for SMT (Surface-Mount Technology) automated pick-and-place reflow soldering or wave soldering fixation. The connector is distinguished by its high soldering strength (ensuring a more secure attachment to the PCB), exceedingly low electrical resistance, stable and reliable connectivity, extended lifespan, and superior durability.

Vacuum blind hole plating technology

Mature design, high-precision processing and advanced vacuum blind hole plating technology are combined to achieve extremely low and stable contact resistance.

Stable contact resistance

Mature design, high-precision processing and advanced vacuum blind hole plating technology are combined to achieve extremely low and stable contact resistance.

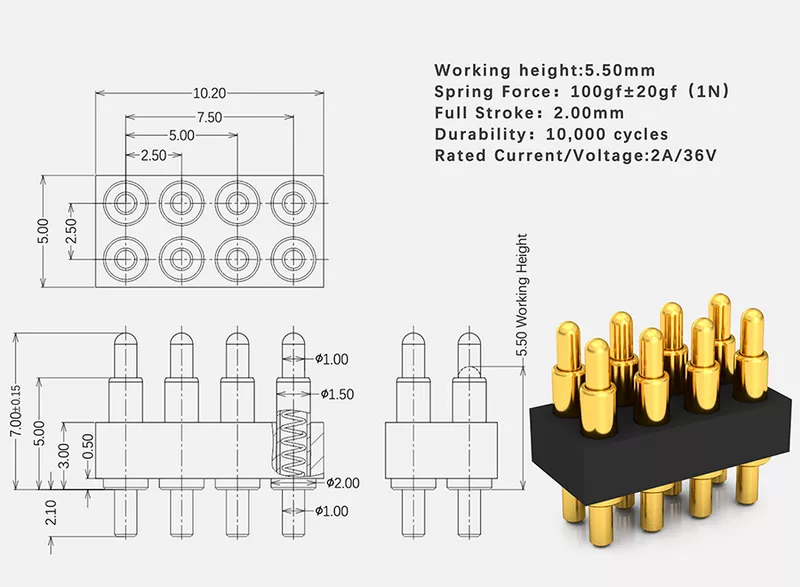

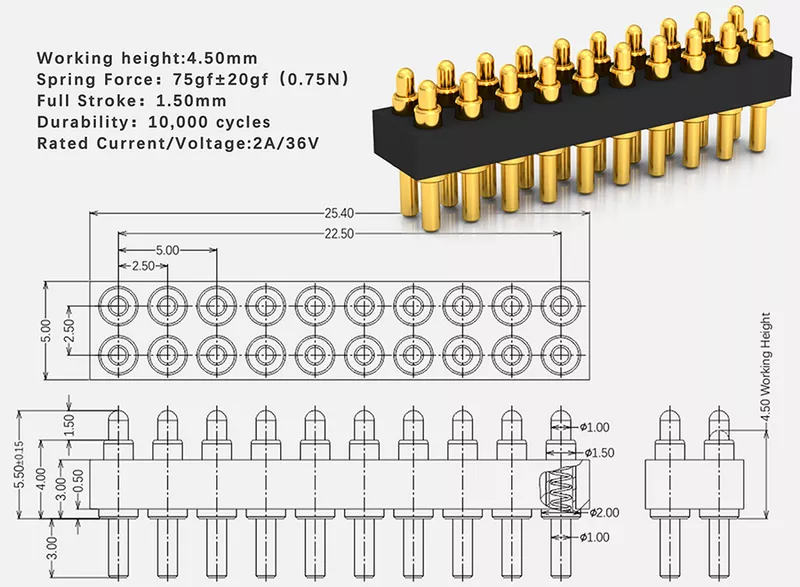

Standard product catalog

| Material: | Main Technical Parameters: |

| ● Plunger: Lead-Free Copper Alloy | ● Standard state: |

| ● Body: Lead-Free Copper Alloy | ● Operating temperature: -40~+120°C(Standard) |

| ● Spring: Stainless Steel | ● Operating humidity: 20-85%RH |

| ● SolidPin: Lead-Free Copper Alloy | ● Storage temperature: -10~+50°C |

| ● Housing: Lead-Free-High Temperature Nylon | ● Storage humidity: 20-85%RH |

| ● Rating voltage: 36V AC/DC(Standard) | |

| ● Rating current: 2A/Pin Continuous(Standard) | |

| ● Contact resistance: 30 mΩ Max.(Standard) | |

| ● Withstanding voltage: 250V AC ,1 Minute | |

| ● Insulation resistance: 500 MΩ Min. | |

| ● Durability:10,000 Cycle(Standard) | |

| ● Working Spring Force:50~180gf(Standard) | |

| Electroplating: | Contact Type: |

| ● Plunger: Ni Plating 1.4μm, Gold Plating 0.30μm | ● Vertical Contact Type |

| ● Body: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| ● SolidPin: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| Installation Method: | Environmental Protection Standard : |

| ● SMT automatic placement machine+Reflow soldering | ● Comply with EU RoHS and Reach standards |

| ● Plugin machine + Wave soldering |

| SN | Product Image | Number Of Pins | Pitch | Catalog Download |

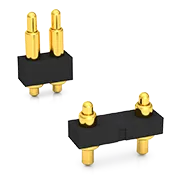

| 1 |  | 2Pin | 2.00~7.00mm | 2Pin-Vertical Dip Pogo Pin Connector |

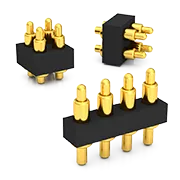

| 2 |  | 3Pin | 2.00~5.60mm | 3Pin-Vertical Dip Pogo Pin Connector |

| 3 |  | 4Pin | 2.00~6.00mm | 4Pin-Vertical Dip Pogo Pin Connector |

| 4 |  | 5Pin | 2.00~6.00mm | 5Pin-Vertical Dip Pogo Pin Connector |

| 5 |  | 6Pin | 2.00~6.00mm | 6Pin-Vertical Dip Pogo Pin Connector |

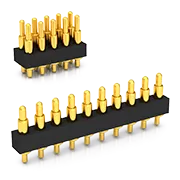

| 6 |  | 8Pin | 2.00~6.00mm | 8Pin-Vertical Dip Pogo Pin Connector |

| 7 |  | 10Pin | 2.00~6.00mm | 10Pin-Vertical Dip Pogo Pin Connector |

| 8 |  | 12Pin | 2.50mm | 12Pin-Vertical Dip Pogo Pin Connector |

| 9 |  | 14Pin | 2.50mm | 14Pin-Vertical Dip Pogo Pin Connector |

| 10 |  | 20Pin | 2.00~2.50mm | 20Pin-Vertical Dip Pogo Pin Connector |